某型锥口罩冲压工艺及其模具设计(含任务书,开题报告,论文说明书6000字,外文翻译,答辩ppt,cad图纸)

摘 要:冷冲模是广泛运用的模具之一,种类包括冲孔模、落料模、弯曲模、拉深模等,近年来冷冲模的应用越来越广泛。冷冲压具有成本低,产品质量稳定,能加工多种性能,状态的零件。同时它的应用和普遍也受到模具寿命和生产安全等方面的制约。

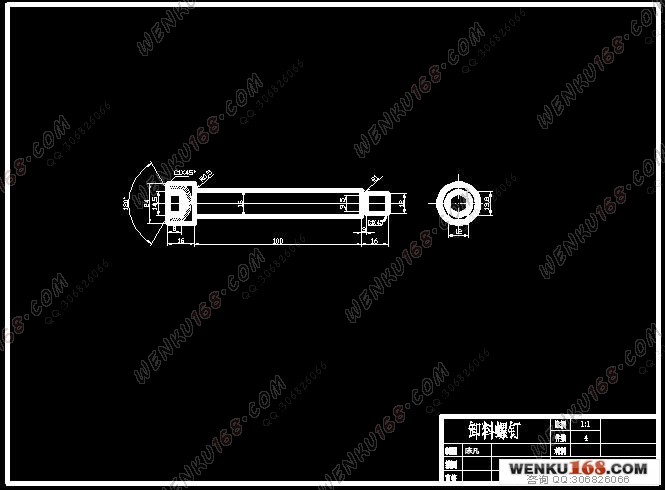

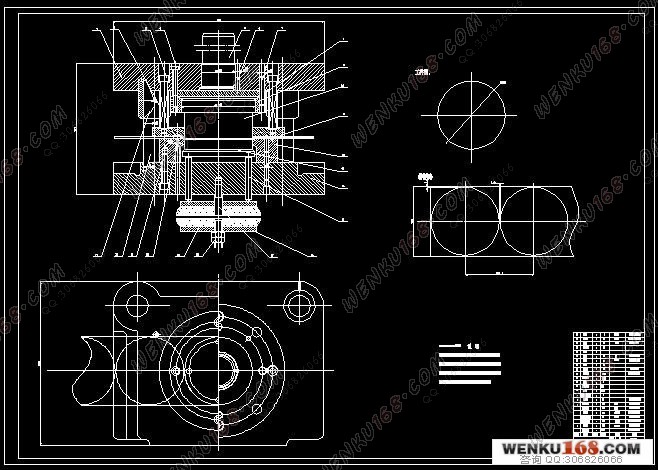

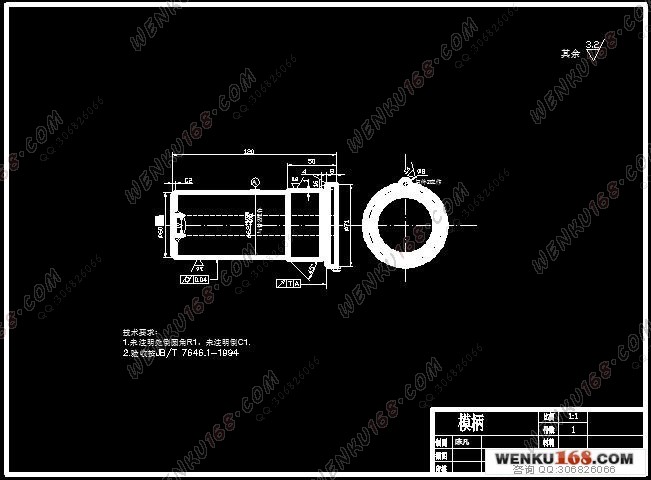

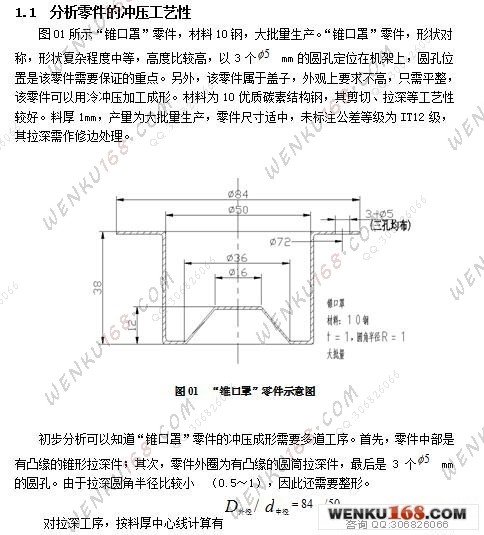

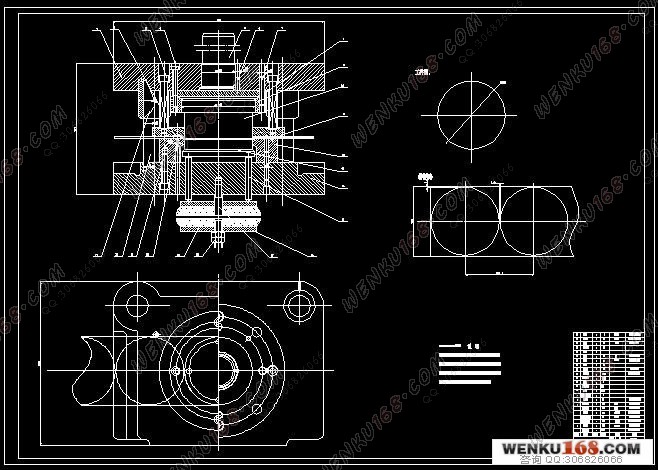

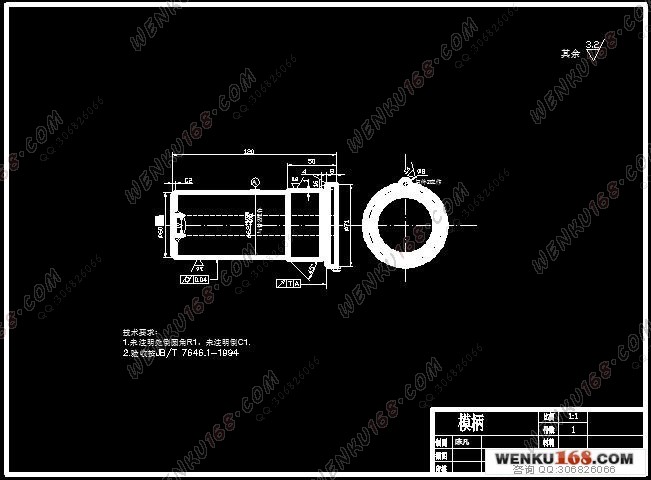

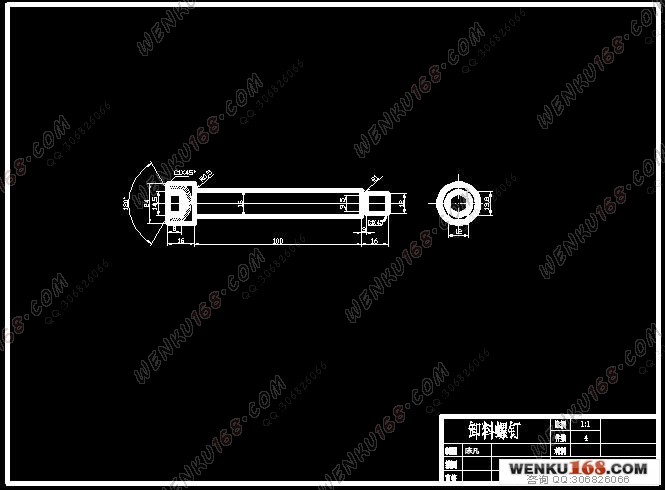

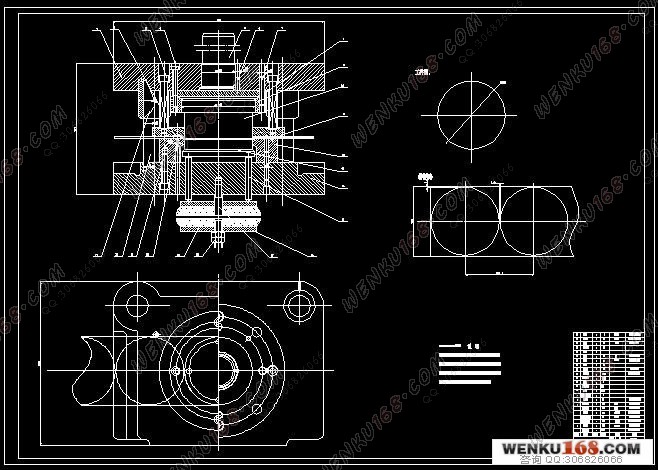

我从工艺的合理性出发,分析了“锥口罩”的结构,精度特点,以及在加工过程中的控制点,然后在满足加工精度的基础上充分考虑节约成本确定了“锥口罩”最优化的冲裁加工工序;紧接着通过熟悉各类模具的加工特点及内部结构,完成模具总体结构分析;随后作者进行毛坯尺寸、排样、工序尺寸、冲压压力、压力中心、模具工作部分尺寸等工艺计算,力争以最好的性价比设计了模具各零件的结构及装配关系,在此基础上确定模具的外形,完成了装配图和非标准的零件图。最后确定压力机类型及主要参数。

关键词:冲孔模 落料模 弯曲模 排样 冲压压力 压力机

"Cone masks" the stamping process and die design

Abstract:Cold punching mould that is used extensively among the all kinds die ,including punching hole mould, blanking die, bending mould, crooked model, conical die etc., The application of the cold punching die is more and more extensive in recent years. It is with low costs that there is the cold punchingly, product quality is steady, can process many kinds of performance , Part of the state. Its application and generallying receive the restriction in life-span of the mould and production safety,etc. at the same time .

Author of this text proceed from rationality of the craft, analyse electrical machinery charcoal pastes up the structure of the shelf , Precision characteristic, and the control point in the course of processing, Consider and economize cost confirm electrical machinery charcoal brush blanking that shelf optimizes most process the process fully on the basis of satisfying the machining accuracy; And then pass the processing characteristic familiar with all kinds of moulds and inside structure, Finish the ensemble architecture analysis of the mould ; Author carry on blank size, arrange kind, process size, punching pressure, pressure in the center afterwards, mould work some size,etc. craft calculate, Strive to design the structure of every part of the mould and assembly relation with the best cost performance, Confirm the appearance of the mould on this basis, has finished the installation diagram and non-standard part picture. Confirm the type of the press and main parameter finally.

Keyword: punching hole mould blanking die bending mould crooked model, conical die Arrange kind automatic punching machine.

毕 业设计(论文)使用的原始资料(数据)及设计技术要求

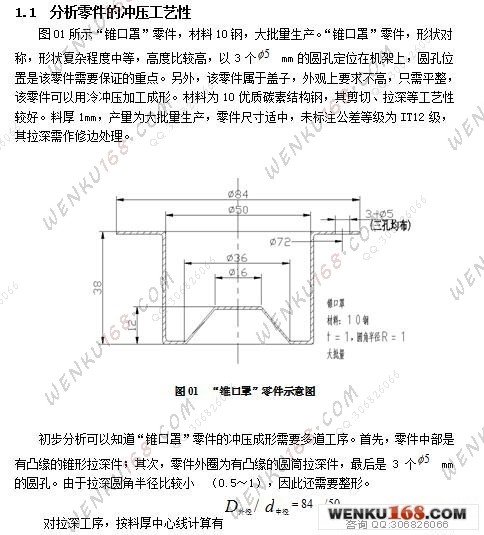

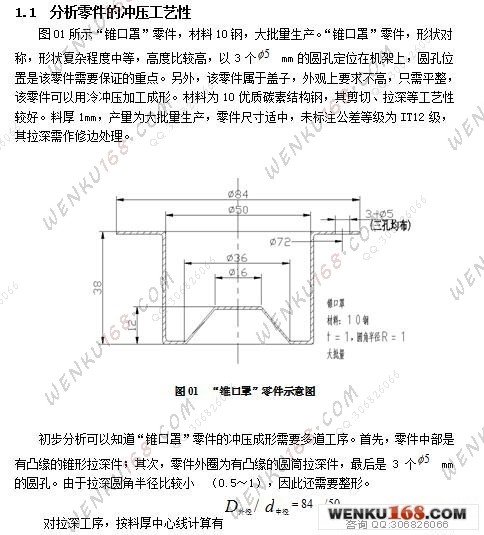

给定某锥形盖零件图(如右图),要求根据该图完成以下工作:

(1)分析锥形盖的冲压工艺性,提出并分析几种可行工艺方案。

(2)确定锥形盖的冲压工艺方案;

(3)进行必要的冲压工艺计算;

(4)选定冲模的结构型式;

(5)选择与确定冲模主要零部件结构与尺寸;

(6)校核冲模闭合高度及压力机有关参数;

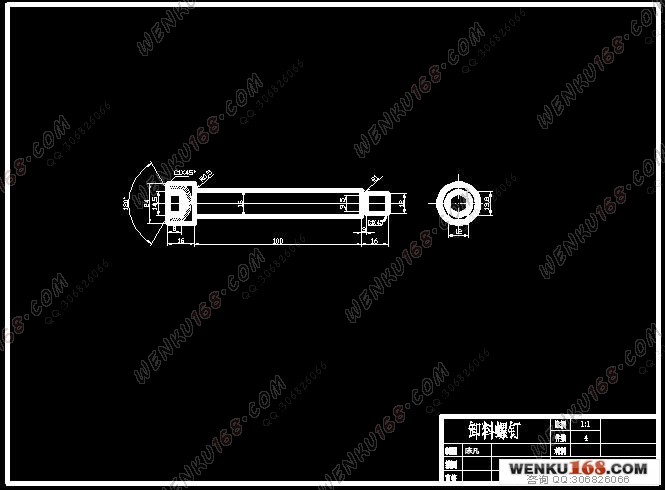

(7)绘制冲模总装图及零件工作图;

(8)撰写毕业设计计算说明书。

|